Views: 0 Author: Site Editor Publish Time: 2026-01-13 Origin: Site

In the road transport sector, a truck’s "configuration code" directly determines its transportation efficiency, application scenarios, and operational costs. From common designations like "4×2, 6×4" to the differentiated model selections across various regions, all these choices are precisely tailored to meet local needs. This article systematically analyzes 20 mainstream truck configurations and sorts out their global regional adaptation logic, providing you with a thorough understanding of the core principles behind truck configurations.

The numbers before and after the "×" in a truck configuration label have a clear definition: the number before = total number of wheels on the vehicle, the number after = number of drive wheels, corresponding to the number of axles and their functional division (axles are categorized into steering axles, drive axles, tag axles, etc.). For example, "6×4" means 6 wheels and 4 drive wheels, corresponding to 3 axles (front axle for steering, tandem middle and rear axles for driving).

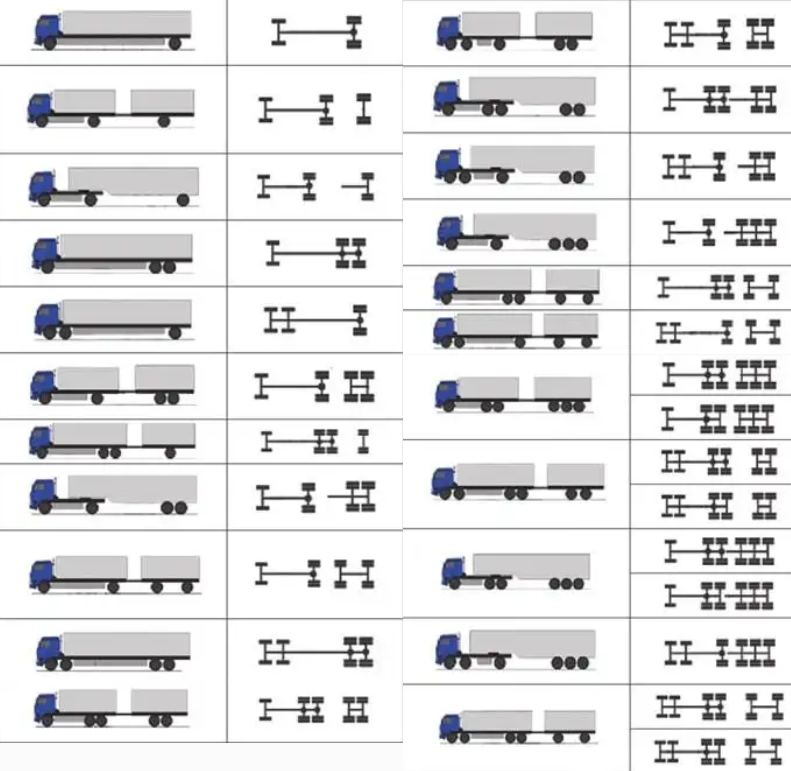

Classified by the number of axles below, this section elaborates on the core information of each configuration, including its definition, structural details, pros and cons, application scenarios, as well as typical domestic and foreign models.

Classification | Number of Wheels × Number of Drive Wheels (by Number of Drive Axles) | Applicable Vehicle Categories | |||||

1 Drive Axle | 2 Drive Axles | 3 Drive Axles | 4 Drive Axles | 5 Drive Axles | 6 Drive Axles | ||

2-axle Truck | 4×2 | 4×4 | - | - | - | - | Mini Truck, Light Truck, Medium Truck, Heavy Truck, Tractor-Trailer |

3-axle Truck | 6×2 | 6×4 | 6×6 | - | - | - | Heavy Truck, Tractor-Trailer |

4-axle Truck | 8×2 | 8×4 | 8×6 | 8×8 | - | - | Heavy Truck, Tractor-Trailer |

5-axle Truck | 10×2 | 10×4 | 10×6 | 10×8 | 10×10 | - | Heavy Truck (Tractor-Trailer Combination) |

6-axle Truck | 12×2 | 12×4 | 12×6 | 12×8 | 12×10 | 12×12 | Heavy Truck (Tractor-Trailer Combination) |

These models are mainly suitable for payload transportation and light off-road scenarios, boasting advantages of high flexibility and low operational costs.

4×2

Definition: 4 wheels, 2 drive wheels (front axle for steering + rear axle for driving)

Structural Details: Front axle is a steering axle, rear axle is a single-stage reduction drive axle, with a wheelbase of 3.5–5 meters

Advantages: Light dead weight (4–6 tons), low fuel consumption (25–30L/100km for highway payload transportation), small turning radius (5–7 meters), low purchase and maintenance costs (15%–20% cheaper than 4×4 models)

Disadvantages: Weak traction (80–120kN), prone to slipping during heavy-load climbing, high single-axle load limit (11.5 tons in Europe)

Application Scenarios: Mainly used for payload long-haul express/less-than-truckload (LTL) transportation and urban light distribution in Europe; also serves as the main model for light cargo transportation in Southeast Asia due to weak infrastructure and cost-priority in vehicle purchase; widely applied in urban express and supermarket distribution scenarios in China

Typical Models:FAW J7 4×2, Sinotruk Howo T7H 4×2, Mercedes-Benz Actros 1845 4×2, MAN TGX 4×2

4×4

oDefinition: 4 wheels, 4 drive wheels (both front and rear axles for driving)

oStructural Details: Front axle is a steering drive axle, rear axle is a drive axle, equipped with a transfer case

Advantages: Strong grip (adhesion coefficient 0.8–1.0), capable of passing through complex road conditions such as mud and snow, with traction 50% higher than that of 4×2 models (150–200kN)

Disadvantages: Increased dead weight (6–8 tons), high fuel consumption (35–40L/100km), high maintenance cost of the steering drive axle (30% higher than that of 4×2 models)

Application Scenarios: Short-haul forestry transportation, engineering emergency rescue, light off-road operations; also used in special scenarios such as desert exploration in the Middle East and short-haul forestry transportation in Africa

Typical Models: Dongfeng Tianjin 4×4, Shacman SX2150 4×4,Iveco Eurocargo 4×4, Ford F-450 4×4

These models cover heavy-haul trunk line transportation and special off-road scenarios, serving as one of the core configuration types in the global transportation sector.

6×2

Definition: 6 wheels, 2 drive wheels (front axle for steering + middle axle for driving + rear tag axle/liftable axle)

Structural Details: Rear axle is a tag axle, which can be lifted when unloaded

Advantages: Light dead weight (7–9 tons, 1–2 tons lighter than 6×4 models), low fuel consumption (30–35L/100km), compliant total weight (≤26 tons in Europe); lifting the rear axle can save 8%–10% fuel consumption and reduce 40% tire wear

Disadvantages: Weak traction of the single drive axle (120–150kN), prone to slipping during heavy-load climbing

Application Scenarios: Mainstream payload long-haul trunk line transportation and urban heavy-haul distribution in Europe (the core reason is that Europe implements axle-based toll collection and has high fuel costs, making lightweight configurations effective in reducing operational costs); in China, its proportion has gradually increased in payload logistics scenarios such as express trunk lines driven by the "lightweight" policy in recent years

Typical Models: Shacman Delong X5000 6×2R, Foton Auman EST 6×2,Volvo FH 460 6×2, Scania G450 6×2

6×4

Definition: 6 wheels, 4 drive wheels (front axle for steering + tandem middle and rear axles for driving)

Structural Details: Middle and rear axles are tandem drive axles, equipped with a balanced suspension

Advantages: Strong traction (200–250kN), capable of climbing 8% slopes with a heavy load of 25 tons without difficulty, high load limit of the tandem drive axles (34,000 lbs ≈15.4 tons in the United States)

Disadvantages: Heavy dead weight (8–10 tons), high fuel consumption (38–45L/100km), high maintenance cost (20% higher than that of 6×2 models), rapid tire wear

oApplication Scenarios: Payload/heavy-haul transportation in the Americas (U.S. regulations are favorable to tandem drive axles in terms of load limits, bringing high returns from heavy-haul transportation); coal and building material transportation in mountainous areas in China (adapting to complex road conditions and heavy-haul requirements); also widely used in trunk line logistics in the Middle East and heavy-haul road sections in Africa

Typical Models: FAW J6P 6×4, Dongfeng Tianlong KL 6×4,Kenworth T680 6×4, DAF XF 480 6×4

6×6

Definition: 6 wheels, 6 drive wheels (front steering drive axle + tandem middle and rear drive axles)

Structural Details: Equipped with a full-time four-wheel drive transfer case and differential locks

Advantages: Excellent all-terrain passability (capable of crossing 0.8m deep water, climbing 40° steep slopes, and traversing 500mm thick snow), extremely strong traction in extreme road conditions (300–350kN)

Disadvantages: Extremely high cost (50%–80% more expensive than 6×4 models), poor fuel economy (50–60L/100km, over 80L/100km in off-road conditions), poor comfort, heavy dead weight (10–12 tons)

Application Scenarios: Military tactical vehicles, fire rescue vehicles, special transportation in polar regions/deserts; core application areas include desert oil exploration in the Middle East and special jungle engineering in Africa; also used in small quantities in forestry and mining areas in northern Canada

Typical Models: Shacman SX2190 6×6, Dongfeng EQ2102 6×6,Mercedes-Benz Zetros 6×6, Tatra T815 6×6

These models are suitable for engineering operations and heavy-haul transportation in complex road conditions, featuring flexible layouts and outstanding load-bearing capacity.

8×2

Definition: 8 wheels, 2 drive wheels (tandem front axles for steering + middle axle for driving + rear tag axle/liftable axle)

Structural Details: Tandem front axles reduce the turning radius, and some models are equipped with a rear steering axle

Advantages: Small turning radius (7–9 meters, 20% smaller than that of 8×4 models), light dead weight (9–11 tons), low fuel consumption (35–40L/100km), suitable for urban operations

Disadvantages: Weak traction of the single drive axle, only applicable for payload transportation (≤31 tons), multiple maintenance points due to the multi-axle structure

Application Scenarios: Urban truck-mounted crane transportation, pallet distribution, hook-lift garbage trucks; in Europe, it serves as one of the main configurations for urban heavy-haul distribution due to the axle-based toll collection policy

Typical Models: Foton Auman EST 8×2, Sinotruk Howo G5X 8×2,Scania P410 8×2, MAN TGM 8×2

8×4

Definition: 8 wheels, 4 drive wheels (tandem front axles for steering + tandem middle and rear axles for driving)

Structural Details: Optional "4 front + 4 rear" or "3 front + 5 rear" layouts

Advantages: Strong load-bearing capacity (≤31 tons in China, ≤32 tons in Europe), good traction (220–280kN), flexible layout, suitable for special-purpose superstructures

Disadvantages: Heavy dead weight (10–12 tons), higher fuel consumption than 8×2 models (40–48L/100km)

Application Scenarios: Global engineering dump trucks, concrete mixers, heavy-haul bulk cargo transportation; serves as the main model for heavy-haul mining transportation in North America and Australia, as well as engineering construction scenarios in China; also widely used in complex road condition transportation in northern Canada

Typical Models: Shacman Delong X5000 8×4, Hongyan Jieshi 8×4,Volvo FMX 8×4, MAN TGS 8×4

8×6

Definition: 8 wheels, 6 drive wheels (tandem front axles for steering + middle axle + tandem rear axles for triple-axle driving)

Structural Details: Triple-axle drive system with balanced suspension, equipped with multiple differential locks

Advantages: Extremely strong traction (300–350kN), capable of passing through complex mountainous/mining road conditions with a 30-ton heavy load, uniform load distribution

Disadvantages: Heavy dead weight (11–13 tons), high fuel consumption (45–55L/100km), high maintenance cost (40% higher than that of tandem axles)

Application Scenarios: Heavy-haul coal transportation in mining areas, heavy-duty equipment transportation in mountainous areas; core application scenarios include western mountainous areas in China and mining transportation in Australia

Typical Models: Beiben V3ET 8×6, Sinotruk Howo TH7 8×6,Scania R580 8×6, MAN TGX 8×6

8×8

Definition: 8 wheels, 8 drive wheels (all axles for driving)

Structural Details: Tandem front steering drive axles, tandem rear drive axles, equipped with full-time four-wheel drive and multiple differential locks

Advantages: Superb extreme off-road passability (capable of crossing 1m deep water, climbing 45° steep slopes, and traversing 600mm thick snow), able to tow equipment over 50 tons

Disadvantages: Extremely high cost (100%–150% more expensive than 8×4 models), poor fuel economy (60–70L/100km, over 100L/100km in off-road conditions), extremely poor comfort

Application Scenarios: Military heavy off-road vehicles, polar scientific expedition transportation, special jungle engineering vehicles; also used in extreme off-road scenarios in Australia and Africa, as well as special desert transportation in the Middle East

Typical Models: Shacman SX2306 8×8, Dongfeng EQ2220 8×8,Tatra T158 8×8, MAN HX58 8×8

Beyond the configurations mentioned above, other types such as 5-axle and 6-axle trucks may also be available on the market. These models remain relatively uncommon in applications at present, as they are mainly designed for extreme heavy-haul, special operations or military scenarios, and thus will not be elaborated on further.

From the distribution of mainstream configurations worldwide, it is clear that there are no absolute "superior or inferior" truck axle configurations—only "suitable or unsuitable" ones. For transportation practitioners, when selecting a configuration, they need to focus on local regulatory requirements, transported cargo weight, driving road conditions, and operational costs. For the general public, understanding these "numeric codes" can also help them better grasp the industry logic behind road transportation. Whether it is Europe’s focus on "fuel and cost efficiency", North America’s pursuit of "heavy-haul performance and high efficiency", or China’s strategy of "diversified adaptation", the essence is to make precise matches based on one’s own needs.